The objective of this experiment is to study the characteristics of a buck-boost converter. The circuit will be operated under continuous conduction mode (CCM) and open loop conditions (no feedback).

A buck-boost converter is shown below, with the transistor and the diode making up the bi-positional switch of the power pole.

Turning on the transistor increases the inductor current, thereby the energy stored in the inductor and when the transistor is turned off, the inductor current flows into the output capacitor through the diode, thereby transferring the incremental energy to the capacitor. For a given transistor switching function waveform q(t), shown below, with a switch duty ratio d in steady state, the waveform of the voltage vA at the current port follows q(t) as shown.

When the switch is ON, i.e., q(t) = 1, the voltage across the inductor is Vin. When the switch is OFF, i.e., q(t) = 0, the voltage across the inductor is -Vo. Since the average voltage across the inductor under steady state is zero, from the vL plot in the above image

d × Ts × Vin + (1 - d) × Ts × -Vo = 0

⇒ Vo = d1 - dVin(1)

The inductor current iL comprises of the average inductor current output IL, and the ripple current iL,ripple which ideally flows into the capacitor.

iL(t) = IL (= Iin) + iL,ripple(t)(2)

Applying Kirchhoff's current law, the average inductor current equals the sum of the average input current Iin and the average output current Io

IL = Iin + Io(3)

where, the output current Io is given by

Io = VoR(4)

For an ideal buck-boost converter the input power equals the output power

VinIin = VoIo(4)

Using Eqn. 1 through Eqn. 4

IL = Iin + Io = VoVinIo + Io= 11 - dVoR(5)

The inductor ripple current component is dictated by the inductor voltage since iL(t) = 1L∫vL(t) ⋅ dt. Thus, over a switching cycle, the peak-peak ripple current is given by

ΔiL = VinL × d × Ts = VoL × (1 - d) × Ts(6)

Copy the folder where pre-built example project for this experiment is present, usually in C:\Program Files (x86)\Sciamble\WorkBench v1\Examples\CUSPLab\BasicPowerElectronics\Experiment5 and paste it in a location where the user has permission to edit and save files, like the Desktop folder.

Launch Workbench application.

Pin ( ) the Explorer dock on the right and the Toolbox dock on the left.

) the Explorer dock on the right and the Toolbox dock on the left.

Click the second icon within the Explorer dock,  to open the project.

to open the project.

Navigate to the folder where the pre-built example project was pasted in Step 1. Double click the BuckBoostConverter.project node within that folder to open the project.

Click the  icon to explore the files within the project.

Double click the

icon to explore the files within the project.

Double click the  BuckBoost node in the Explorer dock to display the model file.

BuckBoost node in the Explorer dock to display the model file.

Ensure that the switching frequency is set to 100 kHz.

To do this, double click on the project node,  BuckBoostConverter, in the Explorer.

Go to the next page by clicking the

BuckBoostConverter, in the Explorer.

Go to the next page by clicking the  in the property dock or choosing Device configuration from the drop-down menu.

Check that the Frequency within PWM Configuration is set to 100000.

in the property dock or choosing Device configuration from the drop-down menu.

Check that the Frequency within PWM Configuration is set to 100000.

Ensure that the PWM channel is set to the Si power pole. To do this, open the property of the tool labeled Si PWM in the model by double clicking on it. Check that the Channel is set to 1.

Warning

WarningBefore proceeding, ensure that the isolated power supply is powered down and that the USB cable is disconnected.

Magnetics card connection: Replace the existing magnetics card with the Buck/Boost/Buck-boost magnetics card, making sure that all six pins are properly aligned and in contact with the power-pole board, adjusting the angle if necessary.

Warning

WarningNever leave the magnetics card unscrewed. If contact is lost while the converter is running, it has the potential to cause very high voltage due to interruption of inductor current, potentially damaging the converter, or worse, could lead to a safety hazard.

Rheostat setting: Set the slider such that the resistance across the two closest rheostat terminals is 25 Ω.

Power connections:

Connect the O+/O- terminals to the rheostat load:

Rheostat rail: ● O+ (Red)

Rheostat terminal closest to the rail: ● O− (Black)Connect the isolated power supply across I+ and O+ terminal:

DC +ve: ● I+ (Red)

DC −ve: ● O+ (Red) Warning

WarningEnsure that the DC power supply positive is connected to Vin+ terminal and the DC power supply negative is connected to the Vo+ terminal.

Leave the ● I- (Black) terminal floating.

Connect the power supply ground to the ground terminal on the board:

Ground: ● GND (Green)

DSO connections:

Connect DSO channel 1 probe to Ii. Set the following options, if they are supported by the DSO:

Set the probe to 1x.

Set the measurement type as Current.

Set the scaling factor to 4x.

Set the offset at 1.5 V or 6 A.

Set termination to 1 MHz.

Set the channel as inverted.

Connect DSO channel 2 probe to Io. Use the same settings as Channel 1.

Connect DSO channel 3 probe to Vo using the 20:1 attenuator. Set the following options, if they are supported by the DSO:

Set the probe to 1x.

Set the measurement type as Voltage.

Set the scaling factor to 20x.

Set the offset at 0 V.

Set termination to 1 MHz.

Set the channel as default/non-inverted.

Connect DSO channel 4 probe to Sa using the 20:1 attenuator. Use the same settings as Channel 3.

Jumper settings:

Insert jumpers ❶ and ❺ (●) to bypass the external current measurement.

Insert the GaN/Si jumper ❷ (●) to Sa/Sw. This connects the buck-converter inductor to the midpoint of the Si power pole.

Jumper ❸ (●) for the GaN FET’s external diode may remain inserted or removed, since this experiment does not use the GaN power pole.

Insert jumper ❹ (●) to connect the drains of the top switches to the positive DC bus (Vin+).

Remove jumper ❻ (●) to disconnect the capacitors across the switches.

Connect the USB cable to the power-pole board and the computer.

DC power supply settings:

Make sure that the DC power supply is fully turned down to 0 V prior to turning on the supply.

Turn on the power supply and gradually ramp up the voltage from 0 V to 15 V.

If the option is available, set the power supply current limit at 4.5 A.

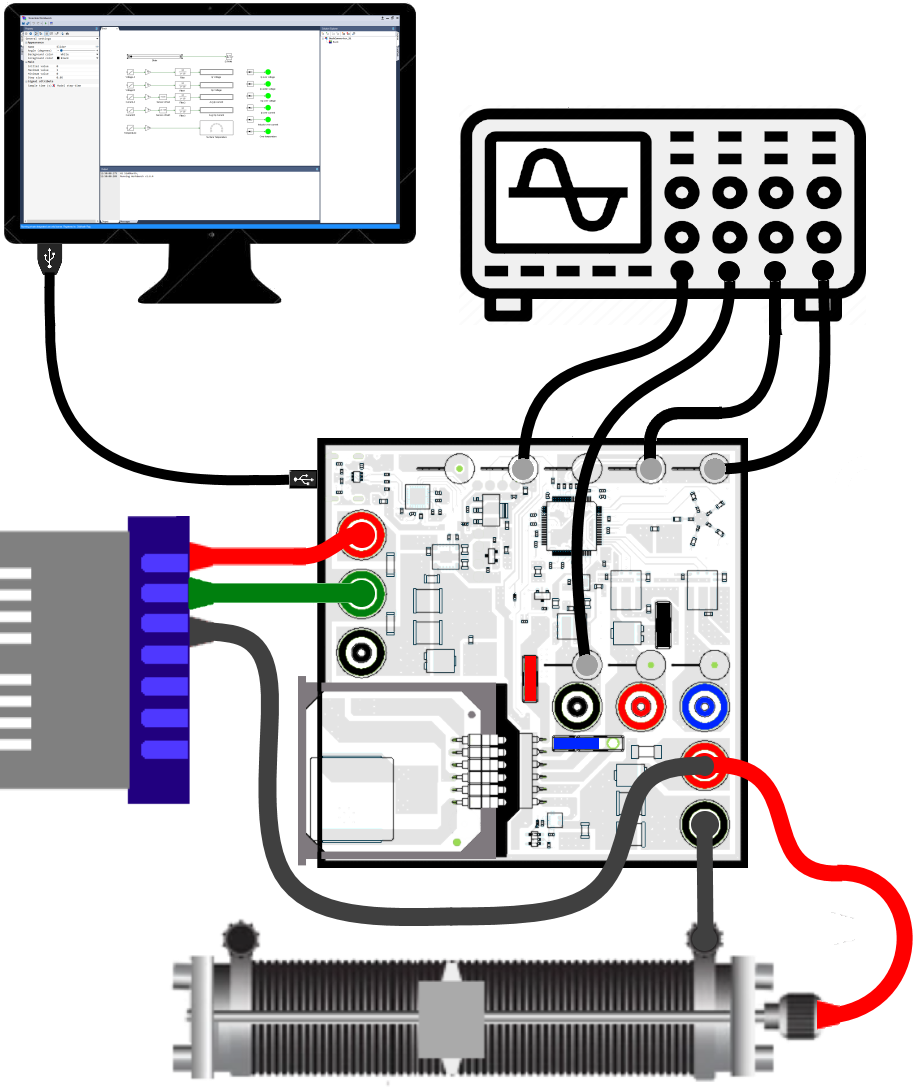

The final wiring should look similar to this:

Click on the  icon in the top dock of Workbench to transition from the simulation mode to the real-time mode.

icon in the top dock of Workbench to transition from the simulation mode to the real-time mode.

Click  to run the control algorithm in real-time.

to run the control algorithm in real-time.

If an under-voltage fault occurs, slightly increase the input voltage above 15 V but less than 16 V.

Stop the model by clicking on  and rerun it.

and rerun it.

Gradually increment the duty cycle from 0 to 0.6 in steps of 0.05. If a fault occurs, stop the model by clicking on  button.

button.

Make the following measurements:

Observe the DSO waveforms and make a copy of the voltage across the switch (channel 4), the output voltage (channel 3), the inductor current (channel 2), and the input current (channel 1) for duty cycle of 0.1, 0.25, 0.4, and 0.6 (or the highest possible value prior to when the fault occured). Adjust the time base to show anywhere between 4-10 switching cycles.

Make a note of the voltage and current values displayed on Workbench, for each duty cycle step.

Click on  to stop the model.

to stop the model.

Change the switching frequency to 100 kHz.

To do this, double click on the project node,  BuckBoostConverter, in the Explorer.

Go to the next page by clicking the

BuckBoostConverter, in the Explorer.

Go to the next page by clicking the  in the property dock or choosing Device configuration from the drop-down menu.

Change that the Frequency within PWM Configuration to 100000.

in the property dock or choosing Device configuration from the drop-down menu.

Change that the Frequency within PWM Configuration to 100000.

Click  to run the control algorithm in real-time.

to run the control algorithm in real-time.

Gradually increment the duty cycle from 0 to 0.3.

If a fault occurs, stop the model by clicking on  button and re-run the model.

button and re-run the model.

Make the following measurements:

Make a note of the voltage and current values displayed on Workbench, at 0.3 duty cycle.

Observe the DSO waveforms and make a copy of the voltage across the switch (channel 4), the output voltage (channel 3), the inductor current (channel 2), and the input current (channel 1) at 0.3 duty cycle. Adjust the time base to show anywhere between 4-10 switching cycles.

Measure the peak-peak inductor ripple current. This will be used to compute the inductance value.

Click on  to stop the model.

to stop the model.

Repeat this section for PWM frequency of 80 kHz, 60 kHz, and 40 kHz. For these frequencies, it is sufficient to take measurement at just a single duty cycle of 0.3.

Turn OFF the power supply and disconnect the USB cable.

If required, repeat the same experiment using GaN power-pole instead of Si power-pole as demonstrated in Switching characteristic of Si MOSFET/GaN FET and diode.

Attach the DSO waveforms showing the voltage across the diode, the output voltage, the inductor current, and the input current for switching frequency of 100 kHz and duty cycles of 0.1, 0.2, 0.3, and 0.4.

Attach the DSO waveforms showing the voltage across the diode, the output voltage, the inductor current, and the input current for duty cycle of 0.3 and switching frequency of 40 kHz, 60 kHz, 80 kHz, and 100 kHz.

For switching frequency of 100 kHz and duty cycle varying from 0.1 to 0.5 in steps of 0.05, enter the measured values from the Workbench screen capture and calculate the following values:

| dset | Vin (V) | Iin,avg (A) | Pin (W) | Vo (V) | Io,avg (A) | Pout (W) | dact | Efficiency (%) |

|---|---|---|---|---|---|---|---|---|

where, dset is the duty cycle value set using Workbench and dact is the duty cycle (d) calculated using Eqn. 1.

Plot the efficiency as a function of dutyact.

Plot the Vo as a function of dutyset.

For duty cycle of 0.3 and switching frequency of 40 kHz, 60 kHz, 80 kHz, and 100 kHz, enter the recorded values from Workbench and calculate the following values:

| fsw (kHz) | Vin (V) | Iin,avg (A) | Pin (W) | Vo (V) | Io,avg (A) | Pout (W) | Efficiency (%) |

|---|---|---|---|---|---|---|---|

Plot the efficiency as a function of fsw. Comment on the difference in efficiency with respect to switching frequency.

From the plot of inductor current at 100 kHz switching frequency, duty cycle of 0.3, and load resistance of 40 Ω, estimate the buck-boost converter inductor value using Eqn. 6.

"Power Electronics, A First Course," Ned Mohan and Siddharth Raju, Wiley Publication.